The appeal of a DIY garage floor transformation is strong: save money, enjoy the satisfaction of a job well done, and create a custom space. However, garage flooring, especially coatings, isn’t always as simple as painting a wall. Many eager DIYers fall victim to common pitfalls that can lead to frustrating results, wasted time, and a floor that falls short of expectations. At Garage Flooring LLC, we want your DIY project to be a success. Let’s break down the most common mistakes and, more importantly, how to avoid them.

Mistake #1: Skimping on Surface Preparation

The Mistake: This is, by far, the most frequent and most critical mistake. Applying a coating to a dirty, unetched, or damp concrete surface is like trying to glue something to a dusty, oily wall. It simply won’t stick, or it will fail prematurely. Why it Happens: Eagerness to finish, underestimating the time/effort involved, or not understanding the importance of profiling concrete. How to Avoid It:

- Clean Meticulously: Thoroughly clean all dirt, dust, and grease. Use a degreaser for oil spots.

- Repair Damage: Fill cracks and patch holes. Small cracks can become big problems under coatings.

- Profile the Concrete: For coatings, the concrete must be etched or diamond ground to create a profile (roughness) that the coating can bond to. This removes laitance (a weak surface layer) and opens pores.

- Test for Moisture: Excessive moisture vapor transmission (MVT) will cause coatings to delaminate. Perform a Calcium Chloride test to assess your slab’s moisture level.

Mistake #2: Ignoring Temperature and Humidity

The Mistake: Applying coatings when it’s too hot, too cold, or too humid can severely impact cure times, adhesion, and the final finish (e.g., blushing, bubbles, incomplete curing). Why it Happens: Rushing to get the job done, not checking forecasts, or not understanding how environmental factors affect chemistry. How to Avoid It:

- Read Product Data Sheets: Every coating has a specific temperature and humidity range for application and curing. Adhere to these strictly.

- Monitor Conditions: Use a thermometer and hygrometer in your garage.

- Plan Ahead: Choose a clear, stable weather window for your project. Ensure good ventilation.

Mistake #3: Improper Mixing or Application of Coatings

The Mistake: Incorrect resin-to-hardener ratios, not mixing thoroughly enough, or mixing too quickly (introducing bubbles and heating material), leads to uncured spots, poor durability, and aesthetic flaws. Applying coatings too thick can cause curing issues, while too thin can lead to poor coverage and reduced durability. Why it Happens: Rushing, not measuring precisely, or neglecting to use a mixer. How to Avoid It:

- Measure Accurately: Use precise measuring tools for the two parts.

- Mix Thoroughly: Use a hand mixer or a drill with a mixing paddle. Mix for the recommended time (e.g., 2-3 minutes), scraping the sides and bottom of the bucket.

- Follow Pot Life: Once mixed, coatings have a limited “pot life.” Work quickly and efficiently, mixing smaller batches if needed.

- Apply Evenly: Use the correct roller nap size and apply at the recommended spread rate to achieve optimal mil thickness.

Mistake #4: Not Allowing Adequate Cure Time

The Mistake: Driving or placing heavy items on a coated floor before it’s fully cured. This can lead to tire marks, imprints, peeling, and permanent damage. Why it Happens: Impatience, misunderstanding “tack-free” vs. “fully cured.” How to Avoid It:

- Patience is a Virtue: Understand that “tack-free” (dry to the touch) is not “fully cured.” Foot traffic, light objects, and vehicle traffic have different cure times.

- Check Manufacturer’s Instructions: Adhere strictly to the recommended cure times for each stage (e.g., 24 hours for light foot traffic, 3-7 days for vehicle traffic). Polyurea often has much faster cure times than epoxy, which can be an advantage.

Mistake #5: Underestimating Material Needs or Poor Planning

The Mistake: Running out of material mid-job, leading to unsightly seams or mismatched batches, or having excessive waste due to poor cutting/layout. Why it Happens: Inaccurate measurements, not accounting for waste, or underestimating difficulty. How to Avoid It:

- Measure Accurately: Measure your garage dimensions precisely. Account for any alcoves or odd shapes.

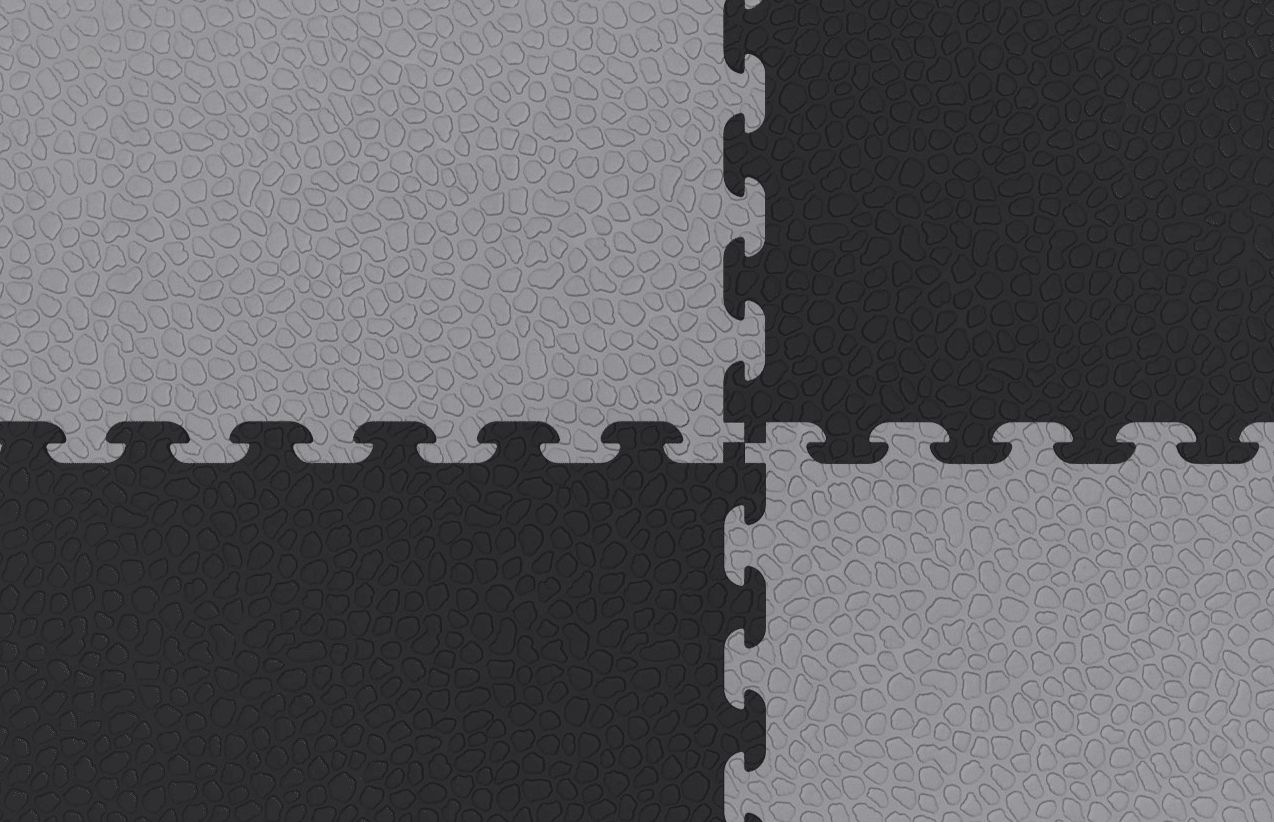

- Plan Your Layout: For tiles, use our Tile Designer Tool to draw out your design and get accurate counts. Plan your starting point and cutting strategy. For tiles, we always recommend getting 5-10 extra tiles in each color to ensure you have enough.

- Stagger Delivery: For large coating projects, ensure you have all material on site before starting.

Mistake #6: Overlooking Safety Precautions

The Mistake: Not wearing proper personal protective equipment (PPE), failing to ventilate, or improper handling of chemicals. Why it Happens: Complacency, rushing, or underestimating chemical hazards. How to Avoid It:

- Wear PPE: Always wear chemical-resistant gloves and appropriate respirators when working with coatings.

- Ensure Ventilation: Open garage doors and windows, and use fans to ensure ample airflow to dissipate fumes.

- Proper Disposal: Dispose of unused materials and contaminated rags according to local regulations.

Mistake #7: Choosing the Wrong Product for the Job

The Mistake: Opting for a cheap “epoxy paint” when a true epoxy coating or polyurea coating is needed for durability, or selecting tiles not designed for heavy vehicle weight. Why it Happens: Prioritizing lowest upfront cost over long-term performance, or not researching product limitations. How to Avoid It:

- Research Thoroughly: Understand the differences between product types (e.g., 1-part vs. 2-part epoxy).

- Assess Your Needs: Consider your garage’s traffic, potential spills, and desired lifespan.

- Consult Experts: Don’t hesitate to contact the professionals at Garage Flooring LLC. We can help you choose the ideal product for your specific application.

Your DIY garage flooring project can be a source of immense satisfaction and a beautiful addition to your home. By being aware of these common mistakes and taking the necessary steps to avoid them, you’ll be well on your way to a professional-looking, long-lasting garage floor that performs beautifully for years to come.

Ready to tackle your DIY garage flooring project the right way?