Workshop garages are the heart of creation and repair, demanding flooring that can withstand heavy use and potential spills. At Garage Flooring LLC, we understand these needs and offer robust solutions designed for the toughest workshop environments. While our flooring options prioritize durability and resistance, it’s important to note that they do not provide anti-fatigue or cushioning properties.

Why Workshop Garages Demand High-Performance Flooring:

- Maximum Durability: Workshops subject floors to heavy tools, equipment, and materials. Our flooring must resist impacts, scratches, and abrasions.

- Superior Spill and Chemical Resistance: Spills of oils, solvents, paints, and other liquids are common. We have flooring options designed to prevent stains and chemical damage.

- Enhanced Safety and Traction: A slip-resistant surface is essential for preventing accidents when working with tools and heavy objects.

- Effortless Cleanup: Workshop messes are inevitable. Our flooring options are designed for easy cleaning, saving you time and effort.

Top Flooring Options for Workshop Garages (Focusing on Durability):

- Polyurea Coatings:

- Polyurea provides exceptional durability and chemical resistance, making it ideal for the most demanding workshops.

- It creates a seamless, non-porous surface that simplifies cleaning and maintenance.

- Its rapid curing time minimizes downtime and gets your workshop back in action quickly.

- This is the best option for chemical resistance, and heavy use.

- Epoxy Coatings:

- Epoxy offers a durable and chemical-resistant surface.

- Installation can be a bit tougher than Polyurea, but the final product will be thicker.

- It’s available in various colors and finishes, allowing for more customization.

- Using a non slip additive is easy, and adds a great deal of safety. Non-slip additive is included with both our epoxy and polyurea kits.

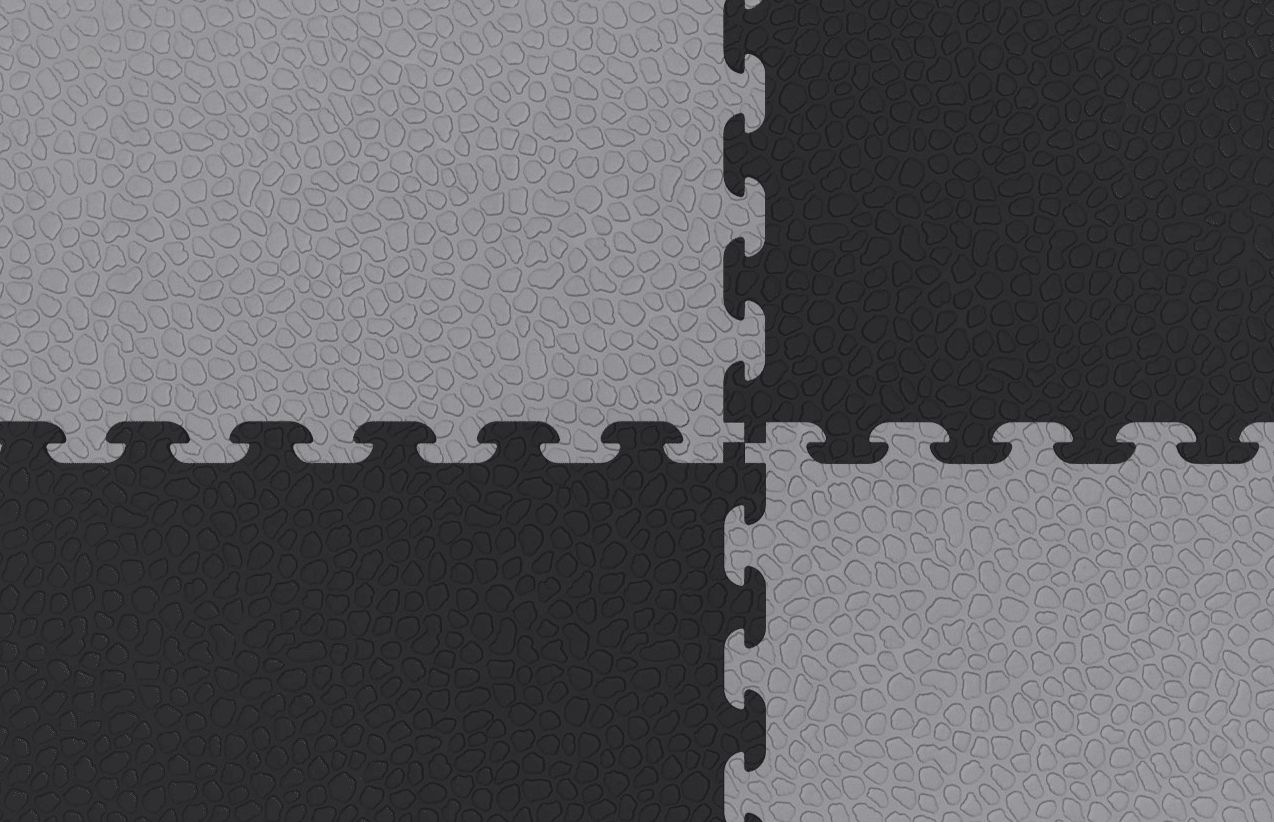

- Garage Floor Tiles (Rigid Interlocking):

- Rigid interlocking tiles provide excellent impact resistance and stability, perfect for heavy equipment.

- They are easy to install and maintain, and they resist stains and chemicals.

- Tiles can be replaced individually if damaged, making repairs much easier compared to a coating.

- Floor tiles are chemical resistant but not watertight, so they may not be the best option for protecting the concrete underneath in areas where a lot of spills are expected. Tiles can be popped up from the middle of the floor to clean underneath as needed.

Important Considerations for Workshop Flooring:

- Impact Resistance: Choose a floor that can withstand dropped tools and heavy objects.

- Chemical Resistance: Prioritize flooring that can handle spills of common workshop liquids.

- Traction and Safety: Select a slip-resistant surface to prevent accidents.

- Ease of Cleaning: Opt for a floor that’s easy to wipe down or hose off.

Creating a Functional and Durable Workshop Space:

Investing in the right flooring for your workshop garage enhances its functionality and safety. At Garage Flooring LLC, we offer high-quality flooring solutions designed to withstand the demands of any workshop environment.